APEX

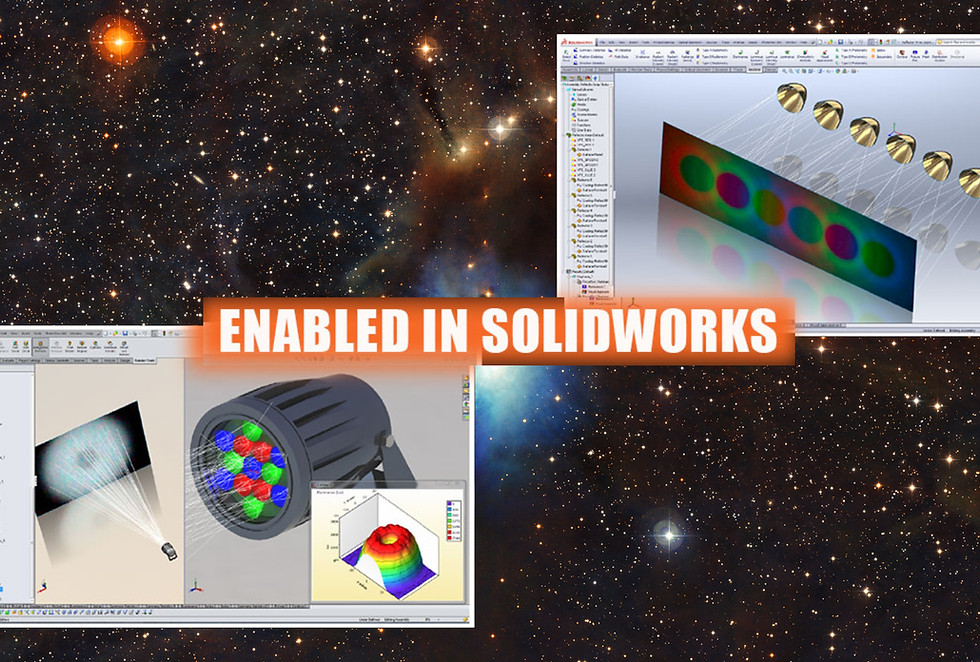

Optical Simulation Enabled in SolidWorks

Optical Simulation Enabled in SolidWorks

APEX

Designing, analyzing and optimizing optical and illumination systems is now at your fingertips! As an optical simulation and illumination add-in to the industry-standard SolidWorks 3D-modeling environment, APEX is tailor-made to meet the requirements of today’s product design teams. Powered by BRO’s kernel technology, APEX uses an easy-to-follow workflow; it facilitates and optimizes design team interactions with optical software tools in a true CAD interface.

With the full power and sophistication of SolidWorks, in APEX there is no need to translate, bridge or link between two separate programs. In APEX, you learn, create, design, analyze, and optimize in the same program environment — and that environment is all about ease of use. APEX seamlessly melds the worlds of computer-aided design and optical engineering, resulting in an “optics aware” design application.

Easy to Follow, Seamless Workflow

FEATURES

No cad restrictions

In APEX, no CAD restrictions are placed on your optical components. Rather, APEX combines the power of SolidWorks geometry modeling with the rigor and precision needed for virtual prototyping of optical systems.

Optical components created in APEX have optical tolerances and blend seamlessly into larger system models, including electrical, mechanical, and other system components.

APEX is an optical engineering application tailor-made to meet the requirements of today’s product design teams — whether big or small. Optical and mechanical engineers can finally work side-by-side on the same files. APEX files are SolidWorks files. Experimenting, evaluating, and innovating is easier than ever with APEX.

WORKFLOW MANAGER

There are two ways to handle system creation for optical analysis in APEX.

ONE: Utilize the fetures of SolidWorks and the APEX add-in to both build the mechanical structures of a system and optimize optical performance. This is the most common, and preferred, workflow of SolidWorks users.

TWO: Utilize the robust CAD interoperability features of SolidWorks to import mechanical designs created in virtually any CAD program, and then optimize optical system performance. This is the preferred workflow for users of other CAD packages.

Following completion of optical analysis in APEX, the optimized optical system can be reimported into the CAD package of choice to continue the engineering workflow.

ASAP ADDITIONAL FEATURES

POWERFUL OPTICAL DESIGN

and analysis add-in for SolidWorks. There is no need to bridge or translate — for a truly seamless workflow.

PARALLEL PROCESSING

APEX automatically runs parallel processes on all cores on a local PC. This provides improved ray tracing speed and efficiency. You can also control the number of cores accessed on each machine. Allocate the number of cores through APEX Project Settings.

SIMPLE WORKFLOW

APEX is easy to use and offers an easy-to-follow engineering workflow.

ACCELERATED ENGINEERING INNOVATION

APEX facilitates and optimizes interactions between engineers with project sharing. Supports collaboration between optical and mechanical engineers.

COMPREHENSIVE LIBRARIES

APEX includes a vast library of sources, lenses, media, coatings, and scatter models that you can incorporate into your design.

OPTICS AWARE

APEX facilitates and optimizes interactions between engineers with project sharing. Supports collaboration between optical and mechanical engineers.

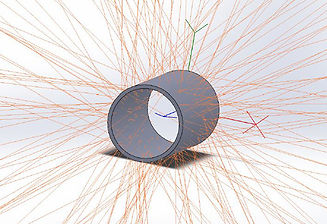

NON-SEQUENTIAL RAY TRACING

Fast and accurate optical simulation via non-sequential ray tracing.

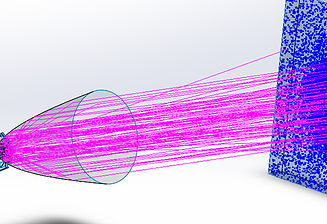

USER-DEFINED GEOMETRY

APEX allows users to define optical geometry types, including lenses and mirrors, with terminology native to optical engineers. APEX accepts polynomials and other optical parameters and will model these surfaces exactly.

FLEXIBLE

APEX offers comprehensive and flexible system optimization capabilities.

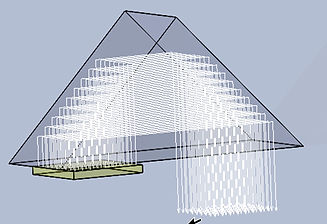

VIRTUAL PROTOTYPING

APEX saves times and money by producing virtual prototypes that reflect real-world results.